how does a crankcase pressure regulator work

The drop in vacuum leads to an increase in RPM which in turn allows more gas to be pulled in. Crankcase Pressure Regulating Valves are designed to prevent overloading of the compressor motor by limiting the crankcase pressure during and after a defrost cycle or after a normal shutdown period.

P052e Positive Pressure Crankcase Ventilation Regulator Valve Performance Description Symptoms Causes Of Error

Work by Infineum using the Turbocharger.

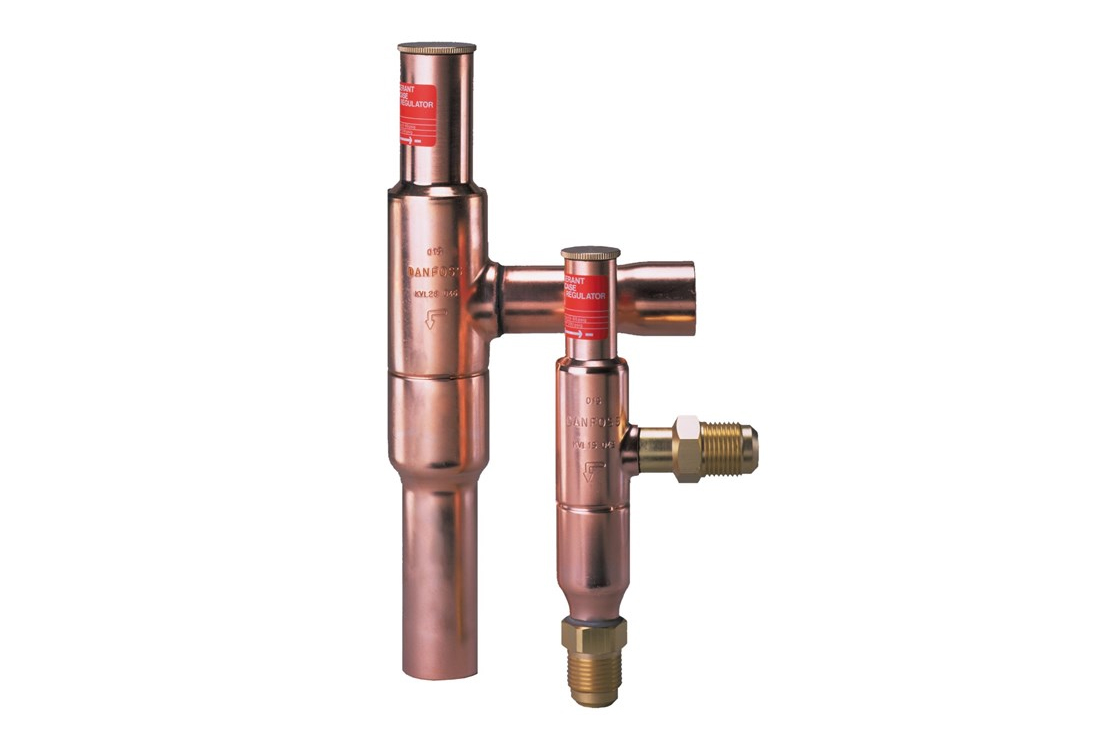

. Pressure regulators reduce a supply or inlet pressure to a lower outlet pressure and work to maintain this outlet pressure despite fluctuations in the inlet pressure. The Danfoss KVL crankcase pressure regulator to a great extend keeps the pressure in crankcase to a reasonable level and further protect the compressor motor. The system usually consists of a tube a one-way valve and a vacuum source such as the intake manifold.

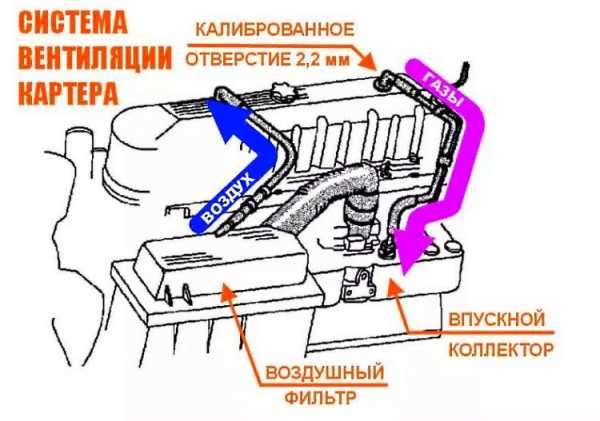

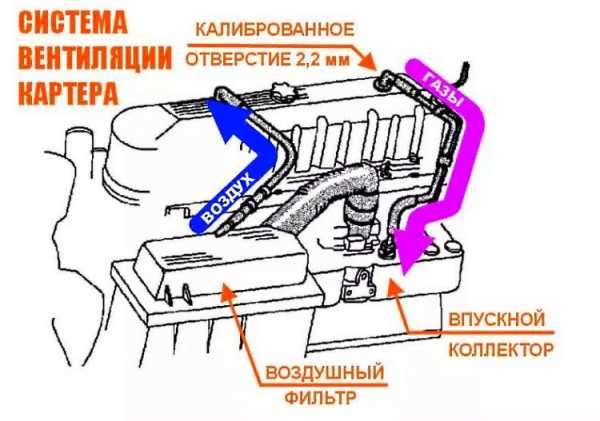

For more information on the standard factory pressure settings of. Since engines produce fumes during the normal running of a car this means it is absolutely crucial for the electronic control module to be able to obtain an accurate crankcase pressure value and. Without a regulator a considerable vacuum could be experienced by the crankcase as the engines air filter accumulates dirt.

When the outlet pressure is correct the valve assembly opens to set the correct pressure. A pressure regulator activates when water travels through the inlet end of the regulator and around the fixed seat as shown above in the dark blue area. The reduction of the inlet pressure to a lower outlet pressure is the key characteristic of pressure regulators.

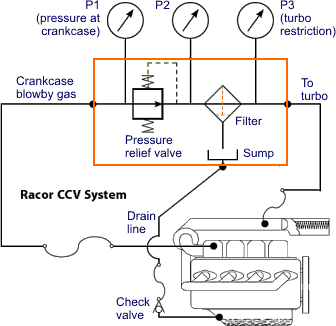

The use of a vacuum regulator vent or pop-off valve is often necessary when running crankcase vacuum. PCV valve on Ford Taunus V4 engine feeding into the intake manifold A crankcase ventilation system removes unwanted gases from the crankcase of an internal combustion engine. The pump can be either electric or mechanically driven but for an ideal solution should be connected to both the block and the valve cover to pull vacuum from both areas efficiently.

Pressure regulators accomplish this by automatically adjusting their opening area based on the inlet pressure. Pressure must be regulated to prevent oil consumption through the intake system and to prevent oil leaks due to excessive buildup of pressure. This is done using a vacuum pump.

Flooded condenser systems are able to maintain pressure within 5 to 10 psig. This is purely to limit the pressure in the compressor crankcase on start up. An adjustment screw on the top of the regulator can be tightened to increase the tension on the inner spring thereby reducing the pressure of the water as it exits the valve or loosened to allow water to flow more freely through the valve thereby increasing the outgoing water pressure.

They open at a specified pressure and allow crankcase pressure to vent to the atmosphere. During circumstances where high intake manifold vacuum is present idle light-throttle cruising and deceleration a PCV valve essentially a one-way check valve in the system allows crankcase pressure to be relieved into the intake manifold the vacuum in the intake manifold helps to draw the pressure from the crankcase. System to relieve pressure in a combustion engines crankcase.

Crank case pressure regulators are normally fitted to condensing unit systems with 1 or multiple evaps and electric defrost hot or cool gas defrost would mean that the compressor is running and therefore the pressure would not increase to an unacceptable level. A Positive Crankcase Ventilation PCV system regulates the vacuum pull through its crankcase. This pressure exits the regulator through the OUTLET AIR PORT.

The opening changes proportionately to help assure the outlet pressure stays within acceptable limits. Adequate pressure drop over a TXV for the refrigerant effect. Control of head pressure is needed in order to maintain.

The Crankcase Depression Regulator CDR Valve maintains crankcase pressure. Our Project Blown Z uses a dry sump system for oiling and vacuum. To prevent flash gas in the liquid line.

The CPR valves are adjustable. When properly installed in the suction line these valves automatically throttle the vapor flow. The suction pressure setting of the CPR must be low enough to protect the compressor.

Parker Hannifin- 207. To provide pressure for hot gas by-pass or hot gas defrost if present. Control is accomplished by regulating the blow-by gases into the intake system to be reburned.

The pressure regulator serves an important function in ensuring that the crankcase pressure does not become too low or too high and exceed the engine manufacturer limits. Another option is to evacuate the crankcase and valve cover by pulling a negative pressure on it. Sporlan Crankcase Pressure Regulating Valves are designed to prevent overloading of the compressor motor by limiting the crankcase pressure during and after a defrost cycle or after a normal shutdown period.

The crankcase pressure sensor is in charge of providing the electronic control module with the right data to keep it working at the right level within the engine crankcase. 900309P CRO-6 12 ODF Crankcase Pressure Regulator 30 to 110 psi SKU. If the outlet pressure is above the pressure set by the range spring the air will go out through the vent above the diaphragm.

Belt or Electric Vacuum Pump. Our Project Blown Z uses a dry sump system for oiling and vacuum. A CPR or crankcase pressure regulator is nothing more than a pressure reducing valve.

Once the vacuum gets higher than desired at idle the PCV valve shuts off and stops that vacuum. The use of a vacuum regulator vent or pop-off valve is often necessary when running crankcase vacuum. This maintains balanced pressure across the diaphragm.

When choosing a pressure regulator many factors must be considered. They open at a specified pressure and allow crankcase pressure to vent to the atmosphere. When installed on a compressor suction inlet and properly adjusted the CPR will prevent the compressor suction pressure from ever rising above the CPRs setting.

R 3 Controls Valves Accessories Heat Pumps 2

What Is The Function Of A Crankcase Pressure Regulator And A Desuperheated Expansion Valve How Do They Work Quora

What Is The Function Of A Crankcase Pressure Regulator And A Desuperheated Expansion Valve How Do They Work Quora

R 3 Controls Valves Accessories Heat Pumps 2

Refrigeration Hvac Crankcase Pressure Regulating Valve Condenser

What Is The Function Of A Crankcase Pressure Regulator And A Desuperheated Expansion Valve How Do They Work Quora

Refrigeration Pressure Regulators Flow Controls Parts 1 And 2 Industrial Controls

Ppt Hvacr318 Refrigeration Special Refrigeration System Components Powerpoint Presentation Id 2794054

How A Kvl Crankcase Pressure Regulator Works Working Animation Youtube

Refrigeration Pressure Regulators Flow Controls Parts 1 And 2 Industrial Controls

Thermofrost Parker Crot Crankcase Pressure Regulating Valve

Crankcase Ventilation Systems Engine Fuel Engineering Eng Tips

What Is The Function Of A Crankcase Pressure Regulator And A Desuperheated Expansion Valve How Do They Work Quora

Hvac Crankcase Pressure Regulating Valves Hvac Troubleshooting

Pressure Regulating Valve Crankcase Pressure Regulator Sporlan Cro Series Parker Na